High-impact ways to boost efficiency in your business

via BDC

What is operational efficiency?

Imagine everything runs smoothly in your business. Your products and services are always top quality and on time. Your customers love you, and your employees are motivated and engaged.

Sounds amazing, right? Such a utopia is within reach with the help of operational efficiency.

What is operational efficiency?

Operating efficiently means using resources like time, people, equipment, inventory and money in an optimized way to serve the business. Efficient companies are leaner, agile and more profitable.

Operational efficiency is often mistakenly seen as being just for manufacturing companies and all about buying better and faster machines. Josh Ramsbottom is eager to dispel this myth. He coaches entrepreneurs on operational efficiency as a Senior Business Advisor with BDC’s Advisory Services.

He says service and distribution businesses also achieve impressive returns from efficiency projects.

And you don’t have to buy new technology to achieve significant gains (although it can help). In fact, the first step is usually to better manage your team, processes and information to reduce waste and create more value for customers.

Operational efficiency elevates organizations to a level of business maturity that a lot of Canadian companies today struggle with. They tend to tell us, ‘We should have done this years ago.’

Operational efficiency helps eliminate waste

By some estimates, just 15 to 20% of an employee’s workday is spent on purely productive activities in the average Canadian small and medium‑sized business.

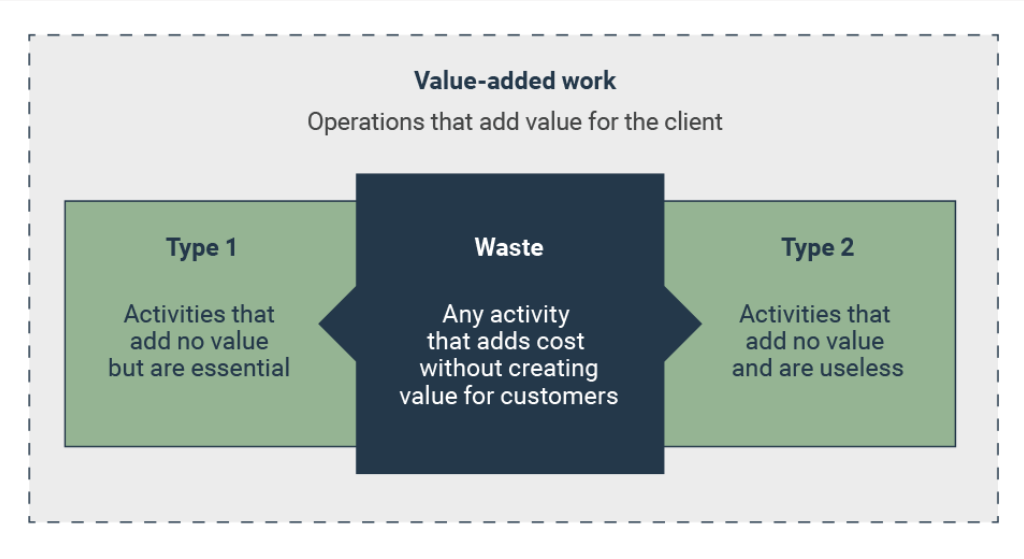

The goal of an operational efficiency mindset is to cut or limit the amount of time spent by workers on non-value-added activities or inefficient processes. By maximizing the amount of value-added work employees do, an operational efficiency exercise can make a business much more competitive and profitable.

Ramsbottom says business leaders are often stunned to realize how much waste actually exists in their company. “We get a lot of surprised, eyebrow-lifting moments,” he says.

What is waste?

What are the benefits of operational efficiency?

Companies are often just as surprised at how simple some of the changes can be, and the substantial benefits, such as:

- reduced costs, lead-time and rates of accidents and errors

- happier customers and workforce

- more clarity for your team about how your business works

- greater adaptability to new business challenges and opportunities, such as those posed by the pandemic

“It pays huge dividends,” Ramsbottom says. “The ROI is seen in multiple areas of the company—from bottom-line savings to more productive and engaged employees who have more pride in what they do. They’re no longer working in an unorganized, chaotic environment, always searching for tools or information or inventory or clarity as to what they’re supposed to be doing.”

Improving efficiency can be a key part of a company’s business strategy, he says. “It elevates organizations to a level of business maturity that a lot of Canadian businesses today struggle with. They tend to tell us, ‘We should have done this years ago.’”

Many entrepreneurs believe the constant firefighting or crisis control means their business is being run effectively. But in reality, the business owner has become a victim of that noise.

Ramsbottom tells of one company that was running out of space in its facility and planning to buy another building. With his advice, the business discovered it was wasting a lot of space in its existing facility and found ways to reorganize its production more efficiently.

By the time the project was complete, the new building ended up no longer being needed and the company wound up with an extra bay in its existing facility, which it was able to sublet out generating extra income.

How to diagnose operational efficiency problems?

Businesses that seek out an efficiency expert often understand they have an operational problem but are too overwhelmed with day-to-day tasks to fix it, or simply don’t know where to start optimizing their business.

Owners or managers are constantly fighting fires

“The typical situation is that a company’s leaders are starting to become bogged down or exhausted from constantly fighting fires,” Ramsbottom says. “They’re bombarded with emergency requests, changing client needs or employees struggling with constant interruptions in their day. These leaders we see are spending all their time being reactive and not adding value by proactively preventing problems before they happen.

“Many entrepreneurs believe the constant firefighting or crisis control means their business is actually being run effectively. But in reality, the business owner has become a victim of that noise.”

Lack of focus on fixing the fundamentals

Operational problems often accumulate over time in unnoticeable ways as businesses grow ad hoc, adding on new employees, machines and processes haphazardly with inadequate strategic planning.

“All of a sudden they realize they have no more space in the building or they have a lot of defects and can’t meet customer demand, or they’re pumping in a ton of overtime but not hitting any of their targets,” Ramsbottom says. “Operational efficiency is about reducing that noise.”

We don’t want to Band-Aid a problem. We want to fix the fundamental issue.

How to improve your operational efficiency?

Like a lot of entrepreneurs, you may suspect there are inefficiencies in your business if you’re experiencing things like declining profits, difficulty meeting demand or even revenue losses.

The good news is you can quickly boost productivity with an operational efficiency drive.

Operational efficiency exercises generally follow these steps.

1. Understand your current state

The first step is to get a good understanding of your company’s current state—what Ramsbottom calls “the good, the bad and the ugly.” A current state assessment typically includes:

- reviewing financial performance

- calculating employee productivity metrics and benchmarking against peer businesses (for example, using the value creation index)

- site visits, interviews and workshops with owners, management and employees to understand the company, including its:

- vision, goals, strategies and culture

- policies and organizational structure

- processes, workflow (e.g. using a process map) and bottlenecks

- analysis of areas of waste (e.g. wasted effort, time, movement, resources or space) guided by lean principles

- scorecarding the company’s efficiency in various areas such as quality control, inventory management and work methods

- studying the main underlying reasons for problems, using tools such as root cause analysis (e.g. a fishbone or ishikawa diagram) and pareto analysis

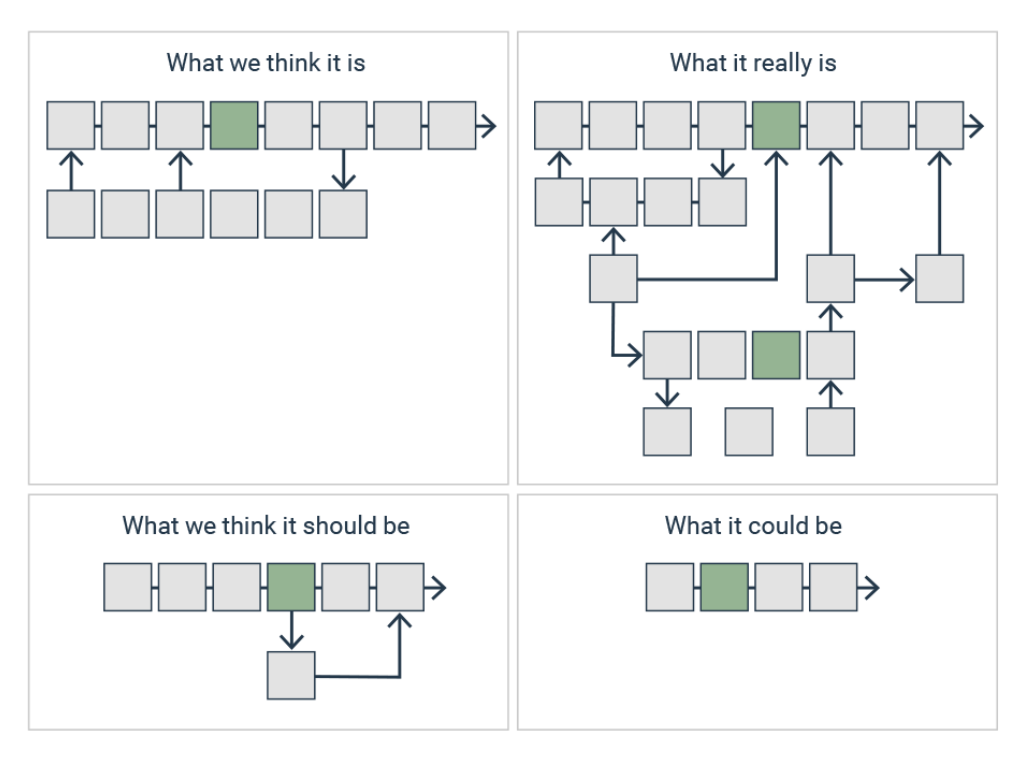

It’s not unusual to see business leaders’ perceptions of how things work differ significantly from what’s actually happening on the ground. “We see a lot of disconnects,” Ramsbottom says.

The truth about business processes

It’s important to get a clear view of the entire business, not just problem areas. “If you just go in and try to solve problems without a good understanding of the whole business, you’re really just doing more firefighting and may not get down to the root causes,” Ramsbottom says.

“We don’t want to Band-Aid a problem. We want to fix the fundamental issue.”

That said, if an urgent problem exists, he may propose a temporary solution to quickly right the ship, then take the time needed to work on longer-term fixes.

2. Develop priority projects and an action plan

The next step is to use the current-state assessment to identify a priority list of solutions that will have the greatest impact on addressing the top causes of problems.

The projects may be broken down into two groups:

- Quick wins that can be completed in the next four or so weeks. It’s useful to have up to three going concurrently and assigned to senior people who have the responsibility and authority to make positive changes.

- Additional projects to be done over six to 12 months. These tend to be more enterprise-level changes that could affect a number of departments or units in your business. It’s important to identify all the stakeholders who need to be involved and empower them to make recommendations and changes.

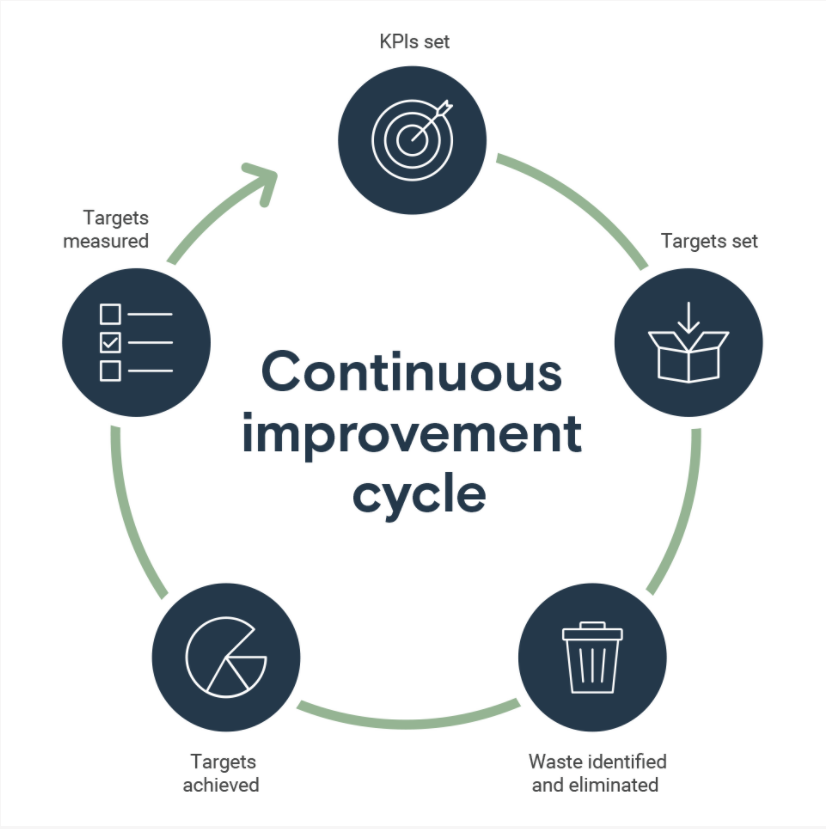

For both types of projects, an action plan should be created that details who will carry out each initiative, a timeline for completion and key performance indicators (KPIs) or milestones to track progress and impact.

Among the projects commonly recommended to many companies:

- Improving supervisors’ management skills.

- Symptoms: Supervisors have little or no management training, projects are unfinished, lack of planning leads to mistakes and delays.

- Solutions: HR management, improving communication.

- Creating a neater, cleaner and more efficient workplace.

- Symptoms: Workspaces are full of clutter, items are lost or misplaced, safety hazards are causing accidents.

- Solution: 5S methodology.

- Implementing a performance dashboard.

- Symptoms: No idea how the business is performing,

- Solution: A dashboard with KPIs and targets.

Be sure to take a holistic view of the business when prioritizing solutions. You don’t want an efficiency project to cause new problems in another department.

Ramsbottom tells of one company that used an efficiency program to triple its production output. What seemed like a great success for the company actually led to chaos in the packaging and shipping departments, which weren’t ready for the higher volumes.

“You have to be careful not to push your bottleneck or challenge downstream,” he says.

Employees have to believe the change is going to be beneficial.

3. Establish the right performance indicators

To meet your production goals, you’ll need performance objectives that are ambitious but realistic.

“Realistic objectives are the catalyst for a culture of operational efficiency,” says Ramsbottom.

Businesses in all sectors can benefit from setting objectives, whether they be manufacturing businesses, distribution centres or service sector businesses.

“If I achieve the objectives,” says Ramsbottom, “it’s because I’ve done well, and the new approach needs to be standardized. If the objective isn’t met, I need to find out why and establish a strategy with the team to achieve it.”

“What you want to avoid is an objective that is never going to be met,” he adds, “while an objective that is met every day is too easy. A middle ground is needed.”

The most common operational efficiency performance indicators

These are some of the most common KPIs used to measure operational efficiency.

Quality

Quality is often measured by looking at the percentage of rejects. This indicator is often combined with an indicator from the customer, whether it be the percentage of returns or the number of customer complaints.

Efficiency

Efficiency or production cost is an important measure for businesses. This indicator is often measured by comparing the time budget for performing an identified task with the actual time spent on that task.

Delivery time

Often considered the most important indicator, delivery time measures the time taken from receiving the order to final delivery, the idea being to significantly reduce production time, waste and mistakes, as well as to increase customer satisfaction. This measure usually has a ripple effect on the other indicators.

Health and safety

Businesses are used to keeping track of the number of days without accidents or the number of days without minor incidents. The COVID pandemic has created a new twist for this metric has businesses had to ensure that no employees were affected by the virus.

4. Implement the change and continually improve

Changes in a business often run into resistance from employees. It’s important to give your team the time, resources and support (including information and training) they need for successful implementation.

- Get buy-in: Explain how the change will solve problems, make their lives easier and lead to more satisfied clients. “Employees have to believe the change is going to be beneficial,” Ramsbottom says. “They really need to be educated on why change is happening and why it’s important in their roles and for their clients. Change for the sake of change never goes well.”

- Meet regularly: Hold regular team meetings to track progress on KPIs or milestones, review dashboards, follow up on production planning, hold everyone accountable, celebrate successes and identify areas for improvement. Many companies hold a brief daily meeting (10 to 15 minutes). In a crisis situation, these meetings can be held twice a day, at the beginning of the shift and at lunchtime, to help teams adapt quickly.

- Update the plan: When the action plan is completed, go back and do the exercise again, creating a new action plan for the next six or 12 months. This creates a culture of continual improvement.

Encourage employee participation: To encourage employee participation, Ramsbottom suggests measuring the number of process improvements introduced by the team. It’s also important to train employees to understand the basics of operational efficiency, such as waste and added value.“Workers are asked to be responsible for implementing their improvements, and the number of improvements made will be measured,” says Ramsbottom. “I like to suggest that employees film their improvements in a one-minute clip. We share the video with the rest of the company, which stimulates creativity and motivates the team.

Encourage employee participation: To encourage employee participation, Ramsbottom suggests measuring the number of process improvements introduced by the team. It’s also important to train employees to understand the basics of operational efficiency, such as waste and added value.“Workers are asked to be responsible for implementing their improvements, and the number of improvements made will be measured,” says Ramsbottom. “I like to suggest that employees film their improvements in a one-minute clip. We share the video with the rest of the company, which stimulates creativity and motivates the team.

“Organizations that continually look at their operations and how to optimize are putting their employees first and ensuring that they’re reducing costs to their bottom line. Everybody wins.”

5. Introduce digital technologies

Businesses should consider digital 4.0 technologies early on as their embark on an operational efficiency journey.

These technologies include, for example, digital manufacturing dashboards, which provide a real-time visual representation of performance indicators. This data will help you alert key personnel to situations that require immediate attention, or detect and analyze the root causes of unplanned downtime and rejects.

A daily management system is another type of software that is indispensable for manufacturing businesses. It enables managers to monitor the progress of a project, task or process on a daily basis. It can also assist in automating workflow, task assignments and reminders, while ensuring that roles and responsibilities are clear.